What are the advantages of water-based ink for gravure printing

Date: Jul 29 2023 From: Star Color Views:

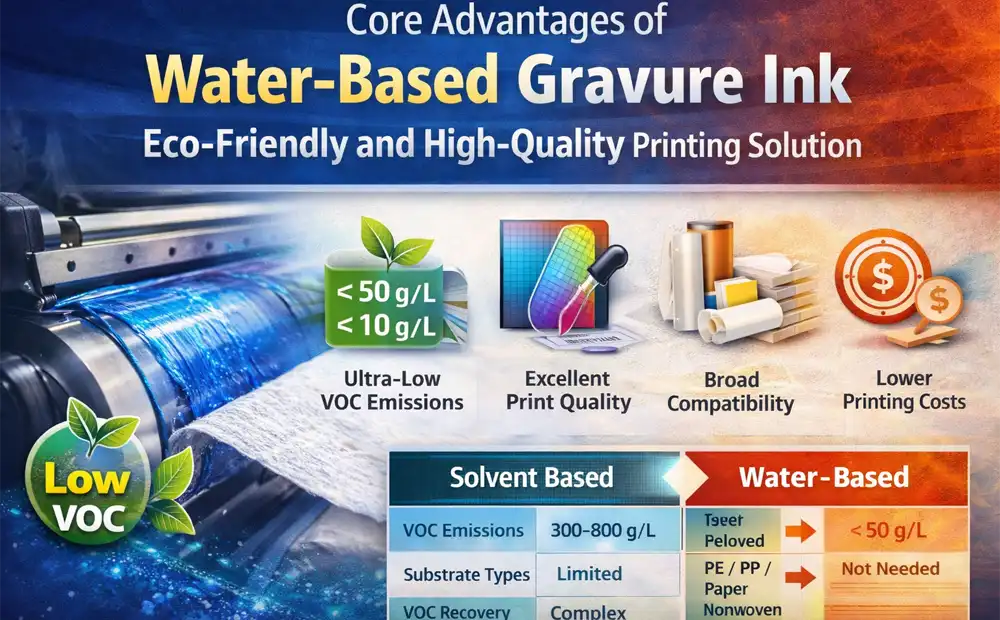

With increasingly strict environmental regulations and growing demand for sustainable packaging, water-based gravure ink is rapidly replacing traditional solvent-based gravure ink. Thanks to its ultra-low VOC emissions and excellent printing performance, aqueous gravure ink has become the preferred solution for flexible packaging, paper, and nonwoven gravure printing.

Compared with solvent-based gravure inks and conventional water-based inks, water-based gravure ink demonstrates clear advantages in environmental compliance, print quality, substrate adaptability, cost efficiency, and operational safety. This article analyzes five core advantages of water-based gravure ink based on real production requirements and technical parameters.

1. Ultra-Low VOC Emissions and Environmental Compliance

Environmental performance is the most significant competitive advantage of water-based gravure ink. Using water as the primary solvent (typically 40–60%), VOC emissions are drastically reduced.

- Low and controllable VOC levels: VOC content is typically ≤50 g/L, and premium formulations can reach ≤10 g/L—over 85% lower than solvent-based gravure inks (300–800 g/L). These values comply with China GB 30981-2024, EU REACH, and U.S. EPA regulations.

- No hazardous solvents: Free from toluene, xylene, and ethyl acetate, water-based gravure ink releases no toxic fumes during printing. Workshop air quality improves significantly, enhancing occupational health and reducing fire and explosion risks.

- Lower waste treatment cost: Waste ink and cleaning wastewater can be treated through conventional processes. Compared with solvent-based systems, environmental treatment costs are typically reduced by 70–80%.

Application example: After switching to water-based gravure ink, a large flexible packaging manufacturer reduced annual VOC emissions from approximately 150 tons to less than 12 tons and achieved green printing certification.

2. Excellent Printing Quality Comparable to Solvent-Based Ink

Gravure printing is known for thick ink layers and high precision. Modern water-based gravure inks are specifically formulated to meet these demands.

- High color strength and opacity: Solid content typically reaches 35–45%, with finely dispersed pigments (0.8–2 μm). Ink film thickness of 8–12 μm ensures vivid colors and strong coverage, suitable for premium packaging.

- High dot reproduction accuracy: With optimized rheology (25–50 s, Zahn Cup #4 at 25°C), water-based gravure inks achieve dot reproduction up to 120–150 LPI and dot gain ≤10%.

- Durable ink film performance: Excellent abrasion resistance, water resistance, oil resistance, and lightfastness meet the requirements of food and daily chemical packaging.

3. Wide Substrate Compatibility

Through resin system optimization and functional additives, water-based gravure ink adapts to a wide range of substrates:

- Non-polar plastic films: Suitable for PE, PP, BOPP, and PET films after corona treatment (≥38 mN/m), achieving adhesion levels of 4B–5B.

- Paper and paperboard: Controlled penetration prevents deformation and mottling, making it ideal for packaging paper and cartons.

- Nonwovens and laminated structures: High-solid formulations reduce excessive absorption, while excellent heat resistance supports lamination processes.

4. Lower Total Printing Cost

Although the unit price of water-based gravure ink may be slightly higher, the total cost of ownership is significantly lower.

- Reduced environmental compliance costs: No need for complex VOC recovery systems, greatly lowering operating expenses.

- Higher productivity and lower waste: Fast drying (surface dry in 3–5 s) supports printing speeds of 200–300 m/min, while defect rates are typically below 0.3%.

- Lower ink consumption per unit area: High solid content and strong opacity reduce ink usage by 10–15% compared with conventional water-based inks.

5. Safe and Convenient Operation

- Non-flammable and non-explosive: Simplifies storage and safety management.

- Easy dilution and cleaning: Can be diluted and cleaned with water or mild detergents, extending equipment lifespan.

- Good storage stability: Shelf life exceeds six months under normal conditions without significant sedimentation or degradation.

Conclusion

With outstanding environmental performance, excellent print quality, broad substrate compatibility, cost efficiency, and safe operation, water-based gravure ink fully meets the demands of modern gravure printing and the global transition toward sustainable packaging.

For printing companies, adopting water-based gravure ink not only ensures regulatory compliance but also enhances product quality, reduces production costs, and strengthens long-term competitiveness.

RU

RU EN

EN CN

CN