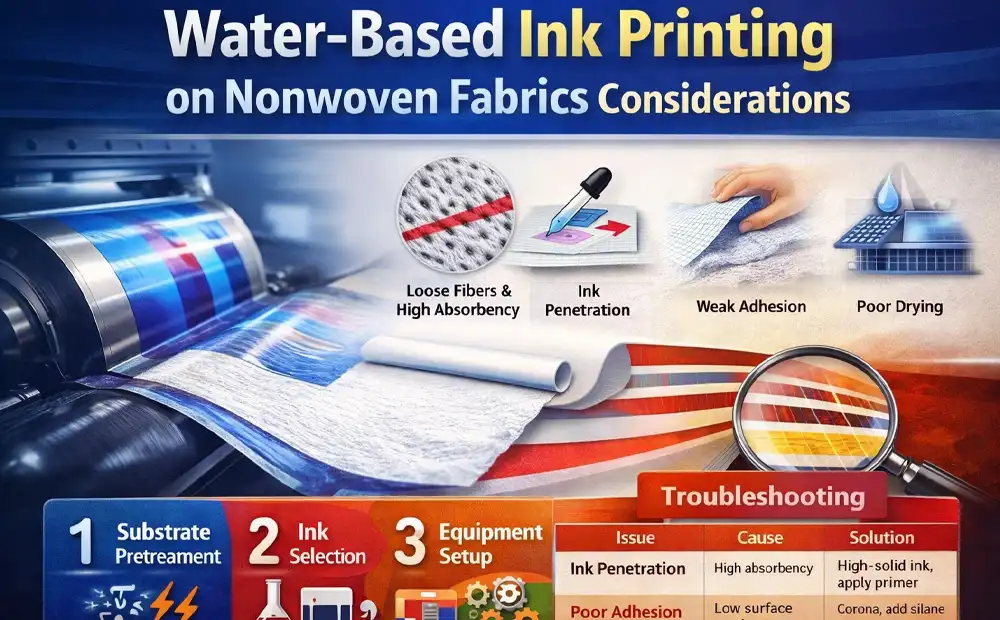

Precautions for water-based ink in non-woven fabric printing

Date: Aug 15 2023 From: Star Color Views:

Nonwoven fabrics are widely used in shopping bags, advertising banners, mask packaging, and agricultural covers. Thanks to their low VOC emissions, safety, and rich color performance, water-based inks have become the mainstream choice for nonwoven printing.

However, the loose fiber structure, strong absorbency, and poor surface uniformity of nonwoven materials often lead to problems such as ink penetration, weak adhesion, uneven color, and poor drying. This article provides a practical technical guide covering substrate pretreatment, ink selection, equipment setup, process control, and troubleshooting to help printers improve quality and reduce waste.

1. Substrate Pretreatment

1.1 Identify Nonwoven Type and Apply Targeted Treatment

- PP nonwoven fabric (over 60% of the market): Non-polar material with low surface tension (28–30 mN/m). Corona treatment is mandatory, with a target surface tension ≥ 38 mN/m. Fine-fiber PP may require double corona treatment.

- PET / viscose nonwoven: Higher polarity and surface tension (≥ 35 mN/m). Corona treatment is optional; if ink penetration is severe, apply a water-based primer instead.

- SMS composite nonwoven: The meltblown layer absorbs ink easily. A water-based sealing primer is recommended to block fiber gaps.

1.2 Control Moisture Content

Nonwoven fabrics are hygroscopic. Excess moisture (>8%) causes ink blooming and weak adhesion, while overly dry material (<3%) leads to fiber brittleness.

- Condition the substrate at 20–25°C and 45–65% RH for 2–4 hours before printing.

- Target moisture content: 4–6%.

- Damp materials should be dried at 40–50°C for 30 minutes before use.

1.3 Remove Surface Contaminants

- Use brushing combined with vacuum suction to remove fibers and dust.

- Install an anti-static device (10–15 cm from the substrate); static level ≤ 500 V.

2. Ink Selection

2.1 Use Dedicated Water-Based Inks for Nonwoven Fabrics

Avoid general-purpose inks. Dedicated nonwoven inks typically feature:

- High solid content: ≥ 45%

- Low viscosity: 15–30 s (DIN Cup #4, 25°C)

- Modified acrylic resin systems for fast film formation

Standard flexo or gravure water-based inks (solid content ≤ 35%) often cause severe penetration and backside staining.

2.2 Select Ink Type Based on Application

- Shopping bags / advertising: High-gloss inks, pigment size 0.5–1.5 μm, gloss ≥ 60 GU (60°).

- Outdoor use: Weather-resistant inks with UV absorbers; ΔE ≤ 1.5 after 1000 h xenon test.

- Food-contact packaging: Compliant with FDA 21 CFR 175.300 or EU 10/2011; VOC ≤ 10 g/L; heavy metals ≤ 0.1 mg/kg.

2.3 Additives (Use with Caution)

- Anti-penetration agent: 1–2%

- Adhesion promoter (PP): 2–3% silane coupling agent

- Fast dryer: 3–5% (ethanol / propylene glycol 1:1)

- Defoamer: 0.3–0.5% (polyether-modified silicone)

3. Equipment Setup

3.1 Anilox Roller / Screen Selection

- Flexographic printing: 80–120 LPI ceramic anilox, volume 20–30 BCM

- Screen printing: 40–80 mesh, screen tension 18–22 N

3.2 Printing Pressure

- Flexo pressure: 0.1–0.2 MPa

- Screen printing squeegee pressure: 0.2–0.3 MPa

3.3 Web Tension Control

- 30–50 g/m² nonwoven: 5–8 N

- 80–120 g/m² nonwoven: 10–15 N

- Rewind tension: 1–2 N higher than unwind tension

4. Common Problems and Solutions

| Issue | Main Cause | Solution |

|---|---|---|

| Severe ink penetration | Low solid ink, high absorbency | Apply primer, use high-solid ink, reduce ink volume |

| Poor adhesion | Insufficient corona treatment | Corona ≥ 38 mN/m, add adhesion promoter |

| Uneven color | Moisture imbalance, poor mixing | Condition substrate, stir ink thoroughly |

| Poor drying | Low temperature or airflow | Increase temperature by 5–10°C, improve airflow |

Conclusion

The key challenge of printing water-based inks on nonwoven fabrics lies in matching the ink system to the material’s high absorbency, loose fibers, and stretchability. From corona treatment and moisture control to dedicated ink formulation, low-pressure printing, stable tension, and proper drying, every step must be precisely controlled.

By establishing a coordinated system covering substrate, ink, equipment, and process, printers can effectively prevent penetration and adhesion issues, achieve stable quality, and expand nonwoven printing applications with confidence.

RU

RU EN

EN CN

CN