RU

RU

EN

EN

CN

CN

Position:HOME > SOLUTION > Gravure Printing

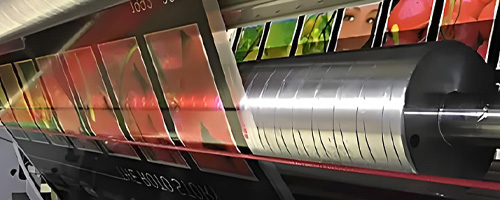

Gravure printing, also known as intaglio printing, is one of the four major printing methods. Gravure printing is a direct printing method that presses the ink contained in the concave pits of the intaglio plate directly onto the substrate.

The shade levels of the printed image are determined by the size and depth of the concave pits. If the concave pits are deeper, they contain more ink, and the ink layer left on the substrate after printing will be thicker. Conversely,

if the concave pits are shallower, they contain less ink, and the ink layer left on the substrate after printing will be thinner.

In 1452, Italian goldsmith M. Finiguira carved intaglio plates. Initially, all the carving was done by hand, but later there was chemical etching. In modern times, mechanical carving has been used as much as possible. The layout is composed of dots and lines of different depths and thicknesses.

In the late 19th century, the Bohemian painter K. Klick used the achievements of his predecessors in photography, carbon paper printing, and other techniques to invent gravure printing and the use of a scraper for gravure printing.

In the mid-20th century, there began to be gravure electronic engraving machines, which used scanning heads and computer-controlled diamond cutting knives to carve ink holes in the shape of an inverted pyramid on a drum, with variations in size and depth

Gravure printing is a highly efficient printing method that occupies an important position in many printing fields due to its high precision, strong anti-counterfeiting properties,

Oct 16 2024

Aluminum foil is a lightweight, high reflectivity, and excellent barrier material that has a wide range of applications in packaging, electronics, construction, and other fields. Printing on aluminum foil can not only

Oct 12 2024

Gravure printing is an ancient yet modern printing technology, with its unique printing effect and suitability for large-scale printing, making it very suitable for book publishing and printing.

Oct 11 2024

Food packaging is not only a key barrier to protect food from external pollution and damage, but also an important component of brand recognition, information transmission, and consumer experience.

Sep 30 2024

When the intaglio factor is printed on paper, the performance of intaglio printing can be well utilized. As paper is an absorbent material, it does not require additional processing and has good

Sep 29 2024

Zhongzhixing water-based ink stands out in the field of cardboard printing due to its outstanding environmental characteristics. Unlike traditional solvent based inks, this ink does not contain harmful volatile organic compounds (VOCs),

Sep 12 2024

Gravure printing, as a printing method with a long history and mature technology, occupies a pivotal position in the printing industry with its unique printing effect and wide range of applications

Aug 28 2024

PET (Polyester Film) film, as a high-performance packaging material, has a wide range of applications in packaging, water-based gravure ink, as an environmentally friendly ink,

Aug 20 2024