UV Flexo Inks

UV Flexo Inks This ink is designed specifically for non-absorbent materials and uses a solvent-free formula to perfectly meet the needs of photo setting printing technology.

In the pursuit of efficient and perfect printing effects, UV Flexo ink has demonstrated its unparalleled advantages. It greatly improves production efficiency with its ultra fast drying speed and excellent printing speed, making printing operations more efficient and efficient.

Series: SC-UV

Printing methods: Flexographic printing

Curing method: UV light

Applicable materials: paper, plastic, film, metal, ceramic

Solvent type: solvent-free

Send Inquiry

Send Inquiry

Product Introduction

Product Name: UV Flexo InkThis ink utilizes UV curing technology to achieve fast drying and efficient environmentally friendly printing effects. With a solvent-free formula, it perfectly meets the needs of photo typesetting and printing technology.

UV flexographic ink not only has excellent printing performance, but also has excellent adhesion and wear resistance. It can firmly adhere to plastic films such as PE, PET, PP, etc., is not easy to peel off, and can withstand friction in daily use, ensuring the durability of printing materials.

It adopts an environmentally friendly formula and solvent-free design to ensure that harmful substances are not released during the printing process, in compliance with international environmental standards.

Product parameters

Type: UV Flexo Inks

Series: SCUV Series

Model: SC100

Fineness:<=10 microns

Color: Customized according to Pantone color code

Printing methods: flexographic printing, letterpress printing

Curing method: UV light

Safety: odorless, non-toxic, and non explosive

Brand: Star Color

Origin: Huizhou, Guangdong,china

Packaging specifications: 5kg, 20kg

Key Features

-

Ultra-Fast Curing

The UV curing process enables instant drying within seconds, significantly enhancing printing speed and boosting productivity while reducing wait times.

-

Eco-Friendly, Solvent-Free Formula

This water-based ink contains no volatile organic compounds (VOCs), minimizing environmental impact and health risks for operators, aligning with green printing standards.

-

Excellent Adhesion & Scratch Resistance

Ensures superior adhesion to various substrates with high resistance to scratches, making printed products more durable during transport and handling.

-

Vibrant Color Reproduction

Through advanced color formulation, UV Flexo Ink offers vivid, high-saturation colors, helping brands achieve strong visual impact in their printed materials.

-

Energy Efficient & Cost-Effective

Unlike traditional solvent-based inks, UV Flexo Ink requires no high-temperature drying equipment, leading to lower energy consumption and reduced operational costs.

Applications

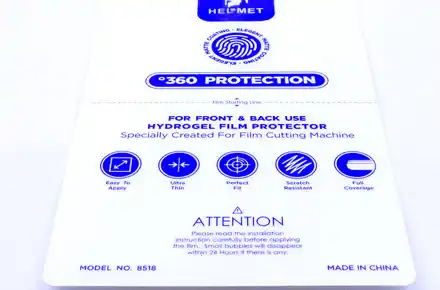

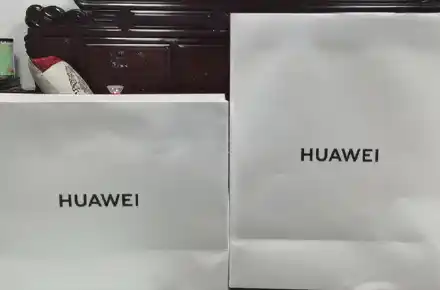

- Packaging Printing: Ideal for food packaging, pharmaceutical packaging, and cosmetics packaging, ensuring product safety and premium print quality.

- Label Production: Perfect for pressure-sensitive labels, shrink sleeves, and various roll materials.

- Industrial Decorative Printing: Suitable for printing on plastic, metal, and paperboard for decorative purposes, such as stationery and household items.

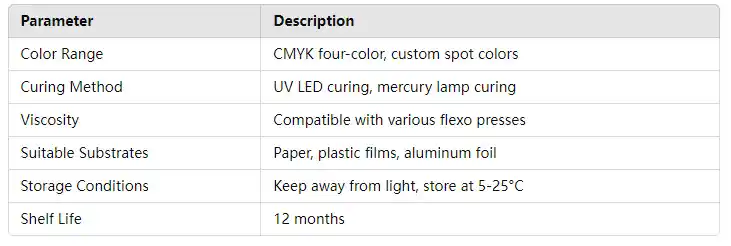

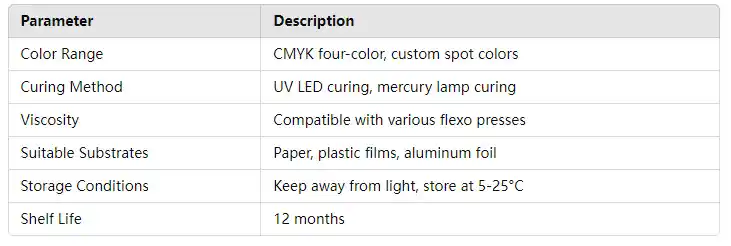

Technical Specifications

Operating Instructions

- Substrate Preparation: Ensure printing surfaces are clean and dust-free. Surface treatment may be required to improve adhesion.

- Ink Tray Adjustment: Adjust ink flow and viscosity according to equipment specifications and printing needs for even distribution.

- UV Curing Equipment: For optimal results, use UV LED lamps to reduce energy consumption and achieve fast drying.

- Cleaning & Maintenance: Use specialized cleaning agents to maintain flexo printing equipment and extend its lifespan.

Frequently Asked Questions (FAQ)

Q1: Is UV Flexo Ink harmful to the environment?

A1: Our UV Flexo Ink uses a water-based formula that is free from VOCs, meeting international environmental standards and ensuring safety for both the environment and operators.

Q2: Can custom colors be produced?

A2: Yes, we offer custom spot color services to match your brand’s color palette, ensuring consistent brand representation.

Q3: How does the ink perform on different substrates?

A3: Our ink has been rigorously tested to provide excellent adhesion and abrasion resistance on various substrates, including paper, plastic films, and aluminum foil.

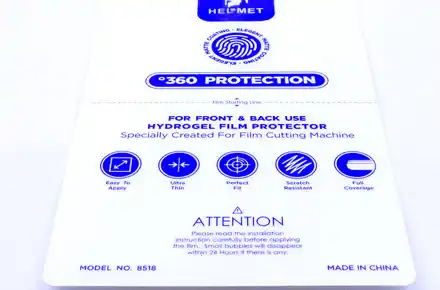

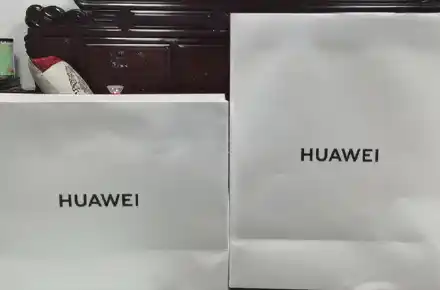

Printing examples

RU

RU

EN

EN

CN

CN