Product Introduction

StarColor Thermochromic Ink is a functional screen printing ink with unique temperature-sensitive properties. When exposed to temperature changes within the range of 10℃ to 65℃, the printed design visibly shifts in color, creating a strong visual impact and interactive effect.

Formulated with high-quality, eco-friendly materials, this ink delivers excellent printability and adhesion on various substrates such as paper, plastics, and films. It is widely used in packaging design, labels, promotional items, toys, and creative printing projects, effectively enhancing product value and market appeal.

Core Technical Advantages

- Precise Temperature Range – Accurate color change within 10℃–65℃, suitable for diverse applications from packaging to novelty products.

- High Printability – Optimized formulation for screen printing, ensuring smooth application, strong coverage, and consistent results.

- Stable & Durable Performance – Reliable color-shifting effect with good resistance to repeated temperature cycles.

- Substrate Versatility – Excellent adhesion on paper, plastics, films, and other common printing materials.

- Eco-Friendly Formulation – Developed with low-VOC, non-toxic raw materials, meeting modern environmental and safety standards.

- Enhanced Visual Appeal – Creates dynamic and interactive effects that capture consumer attention and increase product value.

Technical Specifications

| Parameter |

Specification |

| Product Model |

SCWB-T02 |

| Activation Condition |

10°C--65°C |

| Color Transition |

Customize |

| Printing Methods |

Screen Printing 120-180 mesh |

| Process Temperature |

<200°C |

| Substrate Compatibility |

Medical dialysis paper, coated paper labels, laminated films |

| Adhesion Strength |

≥4B (ASTM D3359 cross-cut test) |

| Storage Conditions |

23±2°C/50±5%RH, protected from light |

| Shelf Life |

12 months (unopened) |

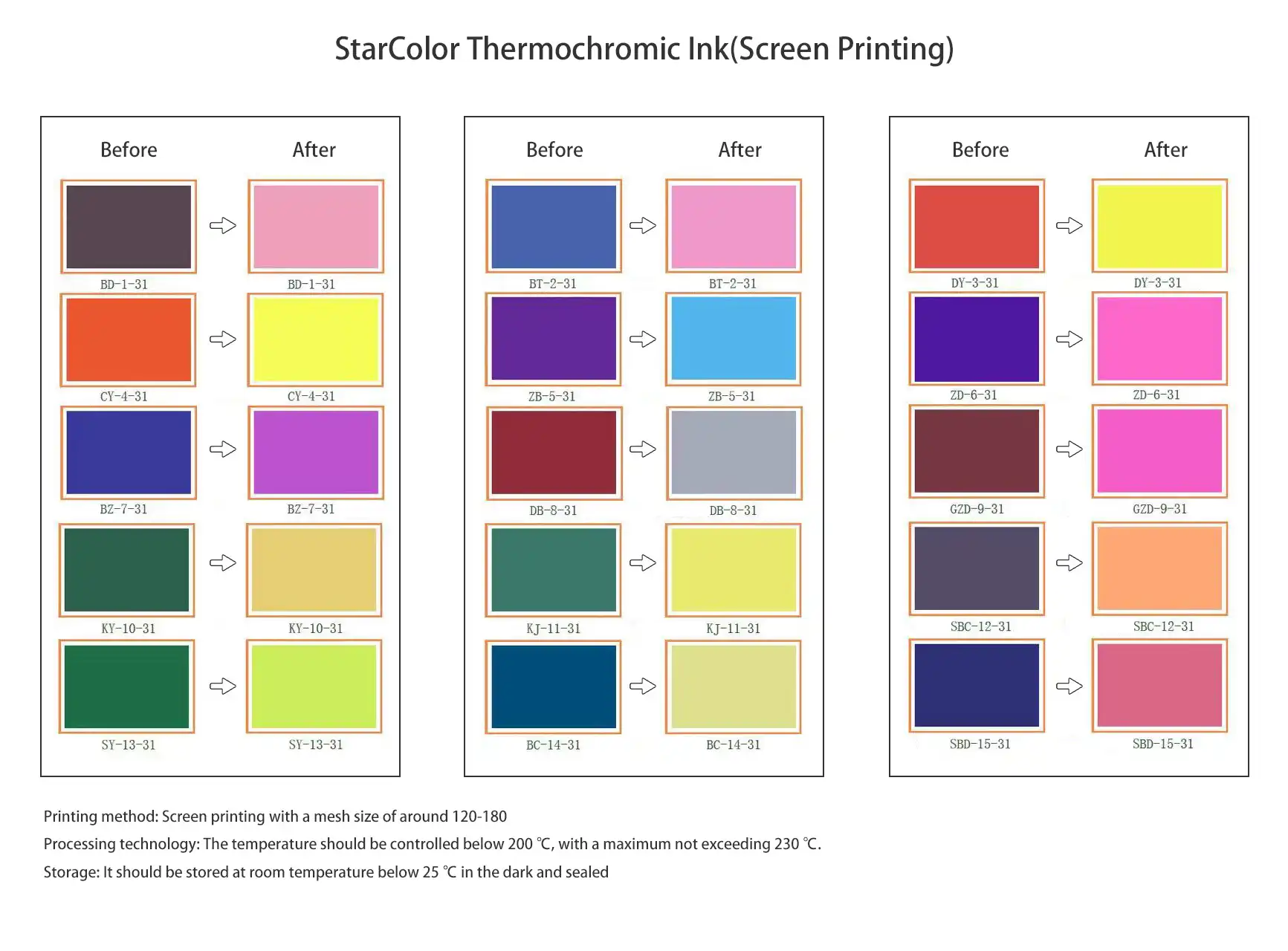

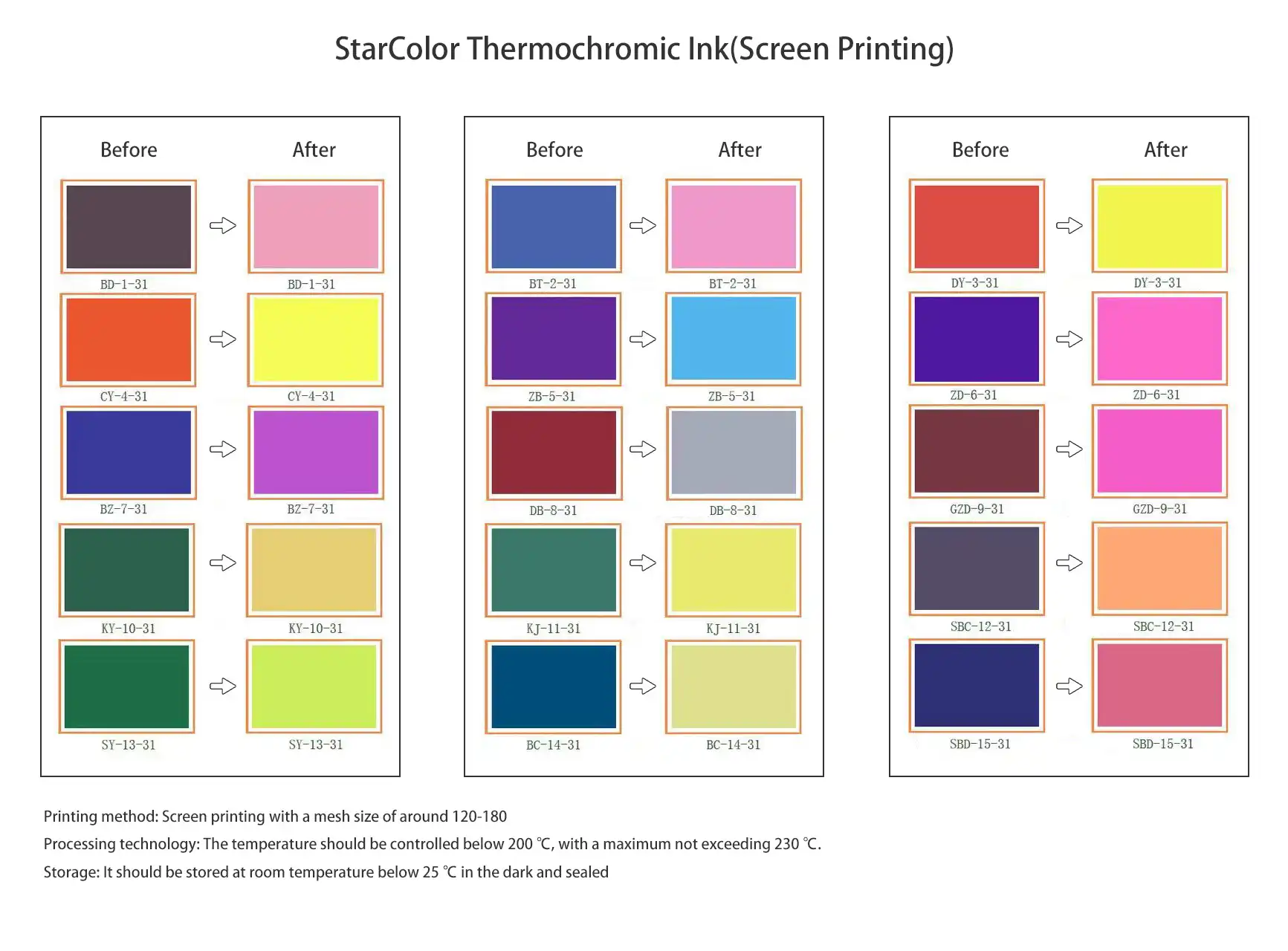

Color Change

What Is Thermochromic Ink?

Thermochromic ink is a type of functional printing ink that changes color in response to temperature variations. Unlike conventional inks, it contains special pigments or microcapsules that react to heat, making printed designs appear, disappear, or shift between colors when exposed to specific temperature ranges.

Typically, thermochromic inks are designed with a defined activation range (e.g., 10℃–65℃). Once the temperature reaches the threshold, the color transformation becomes visible, creating interactive and dynamic visual effects.

Applications of Thermochromic Ink

Thermochromic ink offers unique visual effects that respond to temperature, making it highly versatile across multiple industries. Its ability to shift colors between 10℃ and 65℃ provides both functional and creative value.

Key Applications:

- Packaging & Labels – Used in food, beverages, and pharmaceuticals to indicate freshness, temperature changes, or product authenticity.

- Promotional Materials – Enhances advertising, giveaways, and marketing campaigns with interactive color-changing designs.

- Toys & Games – Adds novelty and fun to children’s products, puzzles, and educational tools.

- Fashion & Textiles – Applied on fabrics or accessories to create dynamic color effects that respond to body heat or the environment.

- Security & Authentication – Provides anti-counterfeiting features for documents, tickets, and branded goods.

- Creative Printing – Used in books, greeting cards, and specialty products to deliver engaging user experiences.

By integrating both practical indicators and creative interaction, thermochromic ink helps brands stand out while improving product value and consumer engagement.

Why Choose StarColor Thermochromic Ink?

StarColor Thermochromic Ink is engineered to deliver both reliable performance and creative impact, making it the preferred choice for screen printing applications. Unlike generic products, our ink combines precise color-changing technology with eco-friendly formulations, ensuring safety, durability, and consistency.

Key Reasons to Choose StarColor:Accurate Temperature Range – Clear and predictable color transformation within 10℃–65℃.

Superior Printability – Specially designed for screen printing with smooth application and strong coverage.

Stable & Long-Lasting – Maintains performance through repeated temperature cycles without fading.

Substrate Compatibility – Works on paper, plastics, films, and other common printing materials.

Eco-Conscious Formulation – Low-VOC, non-toxic design aligned with global environmental standards.

Proven Expertise – Developed by StarColor, a trusted manufacturer specializing in functional and eco-friendly inks.

With StarColor Thermochromic Ink, you get more than just printing ink—you get an interactive, high-value solution that enhances product appeal and strengthens brand differentiation.

RU

RU

EN

EN

CN

CN