Application of flexographic printing on paper bags

Date: Sep 11 2024 From: Star Color Views:

As a traditional and environmentally friendly packaging material, paper bags are gradually replacing plastic bags and becoming a popular packaging choice in the market. Paper bags not only carry goods, but also extend the brand image, and their appearance design and printing quality directly affect consumers' purchasing decisions.

Flexographic printing technology, with its unique advantages and wide application fields, plays an increasingly important role in paper bag production.

Application of flexographic printing in paper bag production

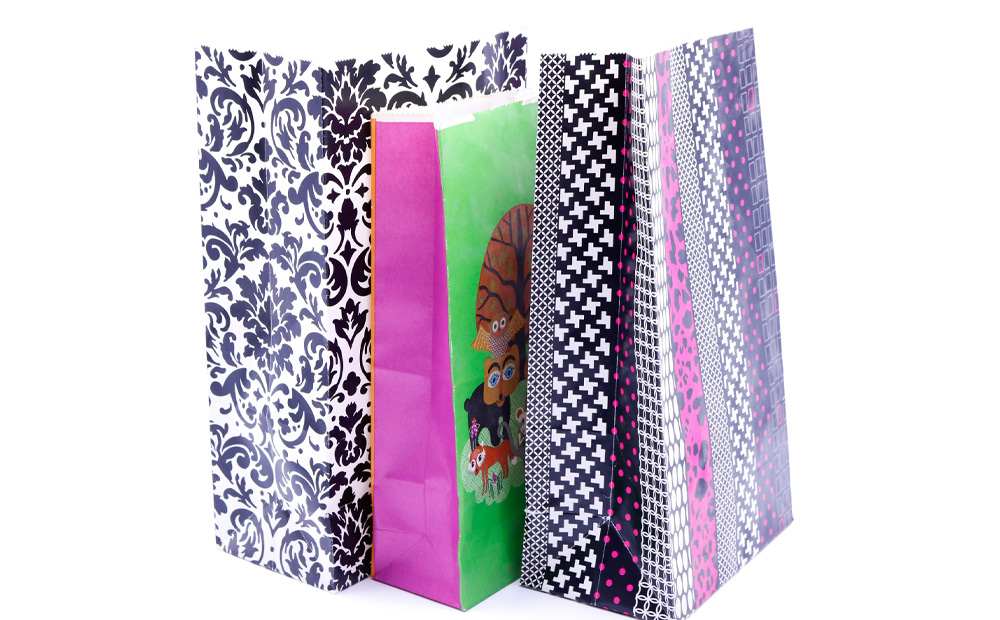

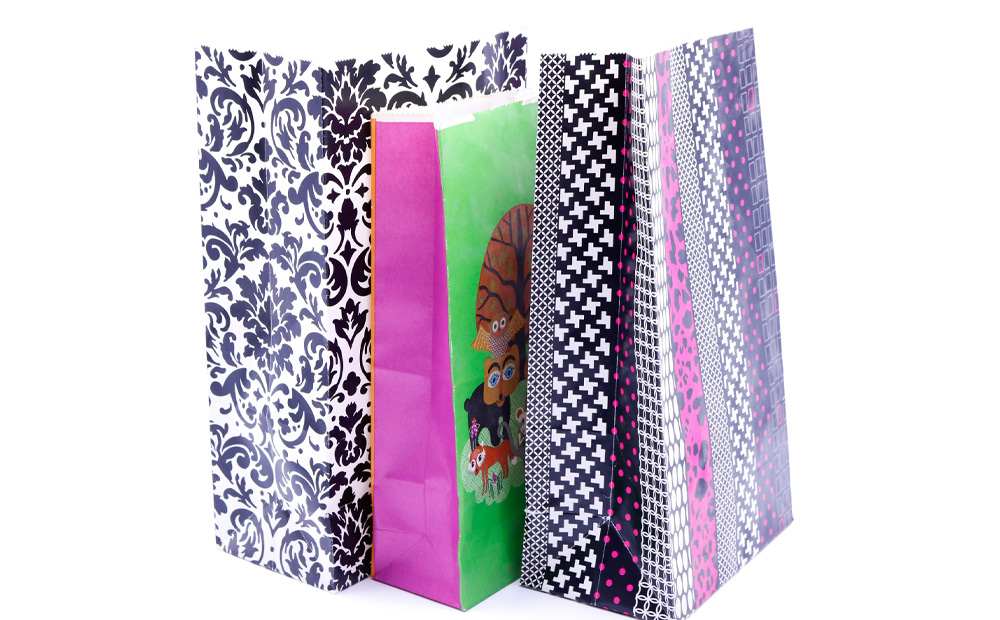

Design flexibilityFlexographic printing technology provides great flexibility for paper bag design. Designers can freely combine elements such as patterns, text, colors, etc. to create a unique appearance of paper bags. Whether it's simple lines, complex patterns, or vivid color combinations, flexographic printing can be easily achieved. This design flexibility not only meets consumers' demand for personalized packaging, but also helps brands stand out among numerous products.

Printing qualityFlexographic printing has demonstrated excellent printing quality in paper bag production. Its high-precision and high-definition printing effect makes the patterns and text on paper bags more delicate and vivid. By adjusting printing parameters such as pressure, speed, and ink volume, the printing quality can be further optimized to ensure that each paper bag achieves the best visual effect. This high-quality printing effect not only enhances the overall texture of the paper bag, but also strengthens the brand's image and value.

production efficiencyThe high-speed and continuous operation capability of flexographic printing machines has significantly improved the overall efficiency of paper bag production lines. With the support of automation and intelligent technology, flexographic printing machines can achieve more precise control and more stable operation. This not only reduces the occurrence of manual intervention and error rates, but also improves production efficiency and output. For manufacturers who require large-scale production of paper bags, flexographic printing is undoubtedly an efficient and reliable printing solution.

The competitive advantage of flexographic printing in the paper bag market

Environmental characteristicsFlexographic printing usually uses environmentally friendly materials such as water-based ink or UV ink, which reduce the emission of volatile organic compounds (VOCs) during the printing process, in line with the development trend of green printing. With the increasing global awareness of environmental protection, consumers' demand for eco-friendly packaging is also constantly growing. Therefore, the environmental friendliness of flexographic printing has become a major competitive advantage in the paper bag market.

Cost effectivenessFlexographic printing also has significant advantages in terms of cost-effectiveness. Compared with other printing methods such as gravure printing, flexographic printing has a shorter plate making cycle and relatively lower plate making costs. In addition, flexographic printing consumes less ink and electricity, thereby reducing production costs. For paper bag manufacturers, this means that while maintaining high-quality printing results, they can reduce production costs and improve economic efficiency.

Stable printing performanceFlexographic printing machines can maintain stable printing performance during long-term operation, ensuring consistent printing quality. This is particularly important for paper bag manufacturers producing in large quantities, as it can reduce the scrap rate and customer complaints caused by unstable printing quality. Stable printing performance not only improves production efficiency, but also enhances the market competitiveness of the product.

In summary, the application of flexographic printing in paper bag production not only reflects its innovative, environmentally friendly, and efficient value, but also brings new development opportunities to the paper bag industry. With the continuous growth of consumers' demand for environmental protection and personalized packaging, as well as the continuous advancement of technology, flexographic printing will play a more important role in promoting the green transformation and sustainable development of the entire paper bag industry.

The Zhongzhixing

water-based ink for flexographic printing, demonstrates outstanding fluidity, ensuring a smooth and efficient printing process. and the printed patterns are clear and delicate, with rich layers and high color reproduction, adding a bright visual effect to paper bags. In addition, the ink has a fast drying speed and strong adaptability, making it easy to handle both high-speed and fine printing, meeting various high-end printing needs.

RU

RU

EN

EN

CN

CN