RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

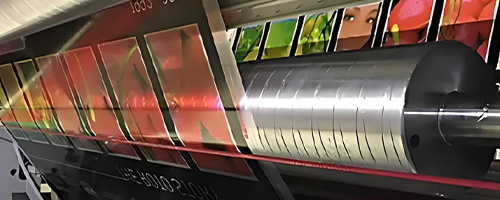

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

water-based gravure inks are gradually replacing traditional solvent-based inks as the new choice for printing enterprises. The market prospect of water-based gravure inks shows a trend of continuous growth

Nov 01 2024

Screen printing involves the use of various assistants, which play crucial roles in ink formulation, printing performance, and print quality. Below is a detailed explanation of the commonly used assistants in screen printing:

Oct 31 2024

For food packaging printing, water-based inks are favored for their environmental impact, low cost, and good printing quality. UV inks, on the other hand, occupy a prominent position in high-quality printing due to their exceptional print quality, abrasio

Oct 29 2024

Absolutely, screen printing can utilize water-based inks. As an environmentally friendly printing material, water-based inks are primarily composed of water-based resins

Oct 29 2024

Generally, the UV flexo inks produced by Zhongzhixing have a pH close to neutral, generally within the range of 7.0 to 8.0. This near-neutral pH helps maintain the stability of the ink,

Oct 28 2024

Food-safe inks are specialized inks used for food packaging and labeling that are designed to pose no risk to human health when in contact with food. These inks have been meticulously formulated to

Oct 27 2024

ater-based gravure inks, as an environmentally friendly printing material, play a significant role in modern printing industries. Their viscosity, a crucial factor affecting printing quality

Oct 26 2024

ater-based inks, as environmentally friendly, non-toxic, non-flammable, and non-explosive printing materials, have been widely applied in packaging, advertising, textiles, and other fields in recent years

Oct 25 2024

The transition from oil-based to water-based inks in gravure printing is a significant advancement in the printing industry,This transition not only contributes to environmental protection

Oct 24 2024

water-based inks are highly favored due to their environmental friendliness and ease of use. However, a notable issue is that most water-based inks exhibit significant intolerance when exposed to alcohol

Oct 23 2024