RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

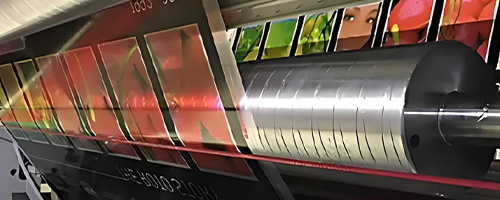

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

During the use of UV flexographic inks, pH value and viscosity are crucial process parameters that directly affect the quality of printed products and production efficiency.

Nov 14 2024

Correctly measuring and adjusting the pH value of UV flexo ink is the foundation for ensuring ink quality, improving printing efficiency, and extending equipment lifespan. By using high-precision pH meters,

Nov 13 2024

Zhongzhixing has developed a flexographic water-based ink that can tolerate 75% alcohol. When printed on paper or plastic film, it will not fade after alcohol wiping. If you are interested, please contact us.

Nov 12 2024

Water-based inks have become the preferred choice in many printing fields due to their environmental friendliness, non-toxicity, and low volatile organic compou

Nov 11 2024

Among the many options, water-based inks have become a popular choice in the market due to their environmental advantages. So, why should companies consider switching to eco-friendly water-based inks?

Nov 08 2024

We know that most flexographic printing uses water-based inks, especially in places with stringent environmental and safety regulations. Water-based inks can be printed on absorbent materials such as paper and also on non-absorbent materials like plastic

Nov 07 2024

When printing on non-woven fabrics with water-based inks, unique issues may arise, primarily stemming from the material characteristics of non-woven fabrics, as well as the adhesion and drying properties of water-based inks.

Nov 06 2024

The above are the common problems and solutions that UV flexographic ink often encounters during printing. We hope it is helpful to you. Troubleshooting UV flexographic ink requires starting from multiple aspects

Nov 05 2024

The author combines his more than 10 years of experience in the industry to briefly compare the costs of water-based ink and oil-based ink in gravure printing

Nov 04 2024

Although water-based inks have already matured, there are still some doubts about their performance. Let's delve into a detailed explanation and comparison of the performance of water-based inks.

Nov 03 2024