RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

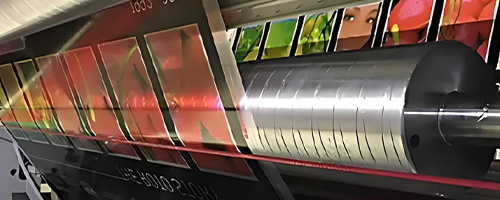

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

In the realm of color management and image processing, CMYK and RGB are two fundamental and crucial color models. They play pivotal roles in different application scenarios

Oct 22 2024

Color fading is a common and complex issue in the process of UV ink printing on aluminum foil. This phenomenon not only affects the aesthetic appeal of the product but may also compromise

Oct 20 2024

there are also those who do not understand this trend and believe that the inks used for printing napkins are unsafe. As a manufacturer of food-grade water-based inks

Oct 19 2024

standard offset printing ink is not food grade. This is because ordinary offset printing ink may contain heavy metals, harmful chemicals, and volatile organic solvents

Oct 19 2024

The viscosity of water-based ink is a crucial parameter in the printing process, directly affecting the quality and effect of the printed materials. Therefore, correctly measuring the viscosity of water-based ink is an important

Oct 17 2024

PET film has a wide range of applications in packaging, electronics, printing, and other fields due to its excellent physical properties and chemical stability. Due to the low surface tension of PET film and its weak affinity for water-based ink

Oct 16 2024

Water based ink printed BOPP (biaxially oriented polypropylene) film has a wide range of applications in packaging, labeling, and advertising fields. However, due to the low surface tension value of polypropylene material itself

Oct 15 2024

UV flexographic ink may encounter various problems during the printing process, which may stem from multiple aspects such as the ink itself, printing equipment

Oct 14 2024

UV ink refers to ink that, under the irradiation of ultraviolet light, uses different wavelengths and energies of ultraviolet light to polymerize monomers in the ink binder into polymers, forming a film and drying the ink.

Oct 11 2024

UV ink, also known as UV curable ink, is a special type of ink that has the characteristics of fast curing speed, minimal color change, and environmental friendliness

Oct 10 2024