RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

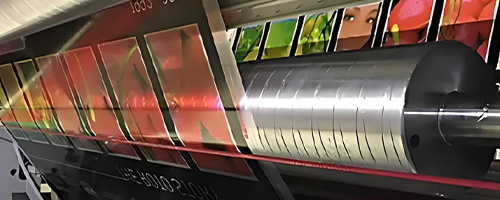

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

As a representative of environmentally friendly printing, soy ink is leading the green transformation of the printing industry with its unique advantages and potential.

Soy ink is renewable, harmless, easy to recycle, and resistant to abrasion, light and

Aug 22 2024

EB ink, also known as accelerated high-energy electron beam ink, is a printing ink based on specific energy curing technology. The uniqueness of this ink lies in its curing process relying on high-energy electron beams rather than ultraviolet (UV) light.

Aug 22 2024

UV ink, also known as UV curable ink, is a special type of ink that can quickly cure into a film under ultraviolet (UV) irradiation. Its uniqueness lies in the fact that its drying process does not rely on traditional solvent evaporation

Aug 21 2024

Recently, someone asked if printing BOPP film with water-based ink would cause color fading, so I am writing this article to explain.

Aug 21 2024

Viscosity is one of the most important indicators in the application of water-based ink, which directly affects the transfer performance of ink, printing effect, and the quality of printed products.

Aug 19 2024

Water based ink flexographic printing, as an environmentally friendly and efficient printing method, has been widely used in modern printing industry. However, in the actual production process, the problem of printing ghosting often troubles printing

Aug 19 2024

Water-based flexographic ink is a kind of water-based ink used for flexographic printing. Its main components are water-soluble resin, organic pigment, water, solvent and related additives

Aug 18 2024

Flexographic printing is an efficient and flexible printing method, widely used in packaging, labels, books, newspapers and other fields. With its unique flexible printing plate

Aug 18 2024

The environmental characteristics of water-based inks, oil-based inks, soy inks and UV inks can be compared from the four aspects of VOC emissions, biodegradability, energy consumption and carbon emissions,

Aug 16 2024

Water based ink occupies an important position in the printing industry due to its environmentally friendly characteristics. It not only significantly reduces the emissions of volatile organic compounds (VOCs) and reduces environmental pollution

Aug 15 2024