RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

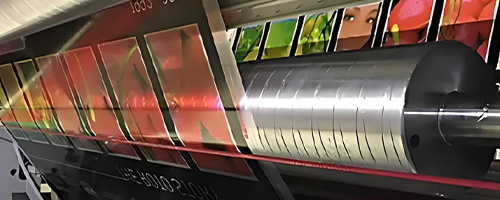

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

There are significant differences between flexographic and gravure inks in various aspects, mainly reflected in ink viscosity, color saturation, suitable materials, printing speed, and environmental friendliness.

Jul 16 2024

UV ink has high adhesion, and once cured, it is difficult to clean off. Some conventional water washes or even alcohol cannot completely clean it off. Cleaning the patterns printed with UV ink

Jul 15 2024

UV ink does indeed fade over time, but the speed and degree of fading are influenced by various factors. The following is a detailed analysis of the fading problem of UV ink:

Jul 15 2024

Whether UV ink is more expensive depends on its comparison with other inks such as water-based ink and oil-based ink, as well as specific factors such as product type, brand, quality, and market supply and demand.

Jul 15 2024

UV flexo ink has been widely used in the printing industry due to its advantages of high efficiency, energy saving, solvent-free emissions, and environmental protection. However, in specific application scenarios,

Jul 13 2024

UV flexo inks are a type of ultraviolet (UV) curable ink used in flexographic printing, a popular printing method for packaging materials. Unlike conventional inks that dry through evaporation or absorption,

Jul 12 2024

UV Flexo inks are a type of printing ink cured using ultraviolet (UV) light. Unlike traditional solvent-based inks, which require evaporation of solvents to dry, UV Flexo inks cure almost instantly when exposed to UV light.

Jul 12 2024

UV ink for flexo printing is a new type of printing method that has emerged in recent years. Flexographic printing, commonly known as flexographic printing, is a universal printing process widely used in packaging materials, labels, and other flexible sub

Jul 11 2024

UV ink and water-based ink each possess unique strengths and applicable fields. UV ink dominates high-end printing with its rapid curing speed, high-quality printing effects, and exceptional wear and weather resistance. Conversely, water-based ink, with i

Jul 10 2024

UV ink and water-based ink, as two mainstream ink types, each possess unique characteristics and application scenarios. UV ink is primarily characterized by its fast curing, applicability to various substrates, high adhesion, and relatively higher price.

Jul 10 2024