RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

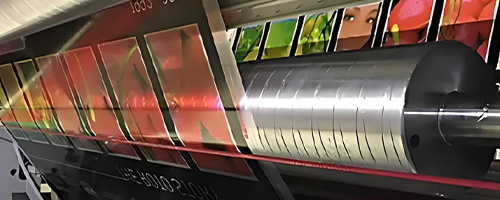

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

In the printing process of water-based ink, additives are often needed to ensure the stability of the ink and the printing effect. These additives can adjust the pH value, viscosity, drying speed, and other properties of ink, thereby overcoming the weakne

Jul 18 2024

The environmental characteristics of water-based ink have been widely recognized, but paper towels come into contact with food. If the ink used to print paper towels is not safe enough, it can cause harm to human health. So, can water-based ink be used to

Jul 17 2024

Aluminum foil can also be printed with water-based ink. Aluminum foil, as a non absorbent substrate, poses a significant challenge to water-based ink printing. However, some aluminum foil products that require food grade printing cannot be printed with oi

Jul 17 2024

ue to its environmentally friendly characteristics, many cardboard boxes now use water-based ink for printing. With the improvement of water-based ink technology in recent years, there have been significant advances in color

Jul 17 2024

Learn which additives enhance the scratch resistance of UV flexographic inks for food packaging. Explore solutions to improve durability, compliance, and performance in printing.

Jul 16 2024

Offset ink and flexographic ink are two commonly used inks in printing enterprises, and there are still significant differences between the two. Offset ink is mostly solvent based ink used in offset printing machines,

Jul 16 2024

There are significant differences between flexographic and gravure inks in various aspects, mainly reflected in ink viscosity, color saturation, suitable materials, printing speed, and environmental friendliness.

Jul 16 2024

UV ink has high adhesion, and once cured, it is difficult to clean off. Some conventional water washes or even alcohol cannot completely clean it off. Cleaning the patterns printed with UV ink

Jul 15 2024

UV ink does indeed fade over time, but the speed and degree of fading are influenced by various factors. The following is a detailed analysis of the fading problem of UV ink:

Jul 15 2024

Whether UV ink is more expensive depends on its comparison with other inks such as water-based ink and oil-based ink, as well as specific factors such as product type, brand, quality, and market supply and demand.

Jul 15 2024