RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

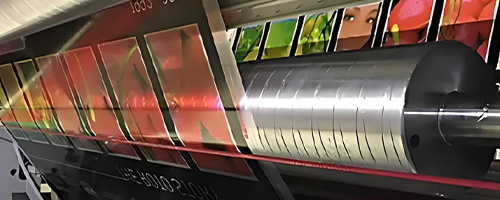

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Learn which additives boost scratch resistance in UV flexo inks for food packaging, enhancing durability and compliance with safety standards.

Aug 27 2025

Discover key tests for assessing food safety of water-based flexographic inks, covering migration, VOC, and raw material compliance for safe food packaging.

Aug 25 2025

Discover effective methods to improve the coverage of water-based flexographic inks on non-absorbent substrates. Learn about ink formulation, surface treatment, and process optimization for consistent print quality.

Aug 21 2025

Learn how to solve poor adhesion issues of water-based flexographic inks on film substrates. Explore root causes, surface treatment methods, and practical printing process adjustments to achieve stronger bonding and better durability.

Aug 19 2025

Learn how to improve the rub and scratch resistance of water-based flexographic inks through resin hybridization, nano-modification, substrate pretreatment, and process optimization. Includes case study with proven performance results

Aug 18 2025

Learn how to enhance printing sharpness of water-based flexographic inks through pigment dispersion optimization, viscosity control, equipment calibration, and process upgrades—solving dot gain, blurred edges, and smudging for high-quality green printing.

Aug 15 2025

Discover how to reduce water-based flexographic printing ink consumption by 20%-30% without compromising quality through high-solid-content inks, anilox roller optimization, and thin-layer printing techniques for cost savings.

Aug 13 2025

Learn how a leading packaging enterprise reduced BOPP printing VOC emissions by 87.5% using water-based inks, covering ink selection criteria, process optimization, and environmental/economic benefits for sustainable packaging transformation.

Aug 11 2025

Explore critical environmental durability and safety tests for water-based flexographic inks, including temperature resistance, chemical resistance, VOC content, and heavy metal detection, to ensure print lifespan and regulatory compliance.

Aug 08 2025

Discover key testing methods for water-based flexographic ink performance, covering basic properties (color, fineness, viscosity), application performance (adhesion, drying speed, dot reproduction), and criteria to ensure print quality and production stab

Aug 08 2025