RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

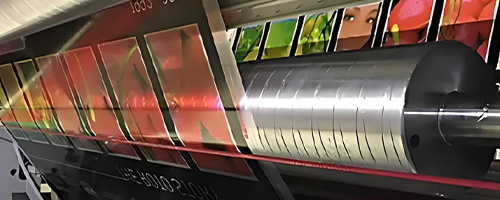

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Author with over 10 years of experience in the printing industry, analyzing the technical pain points of water-based ink printing paper bags, such as low drying efficiency, unstable color difference, and insufficient adhesion

May 16 2025

Starcolor eco-friendly water-based inks have formed a strong differentiated competitive edge through their environmentally non-toxic formula, excellent printing performance, wide applicability, and good economic efficiency and sustainability

May 15 2025

The density of printing ink directly impacts print quality.achieving high-quality prints requires precise alignment of ink density with substrate properties, printing speed, and desired effects.

May 14 2025

the four major systems of flexographic printing inks each have their own characteristics and play important roles in different application scenarios. With the improvement of environmental requirements and the development of printing technology,

May 12 2025

With the vigorous development of green printing technology, acrylic and polyurethane water-based inks have become two mainstream systems, widely used in packaging, textiles, electronics

May 09 2025

Deeply analyze the causes of color difference in gravure printing and provide detailed solutions, as well as real-life cases for reference,

May 08 2025

Analyze the environmental protection system of eco-friendly ink, as well as the VOC emissions, carbon footprint, and certification standards of the five major eco-friendly inks

May 02 2025

gravure printing is widely used in packaging production for food, pharmaceuticals, tobacco, and other sectors due to its high precision, abrasion resistance, and excellent color performance. However, with the trend toward high-speed and automated producti

May 01 2025

Rotogravure printing is a highly efficient and high-quality printing method widely used in packaging production for industries such as food, pharmaceuticals, and daily chemicals. Despite its mature technology

Apr 30 2025

Gravure reverse water-based ink has gradually become the mainstream in the printing industry due to its environmental protection and safety features. However, in the actual production process, it often faces six major core problems:

Apr 29 2025