RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

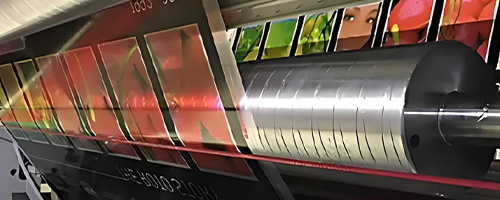

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

some people may have concerns about the safety of the ink used for the patterns and text printed on them. Nowadays, most napkins are printed with water-based ink. So, are water-based ink napkins toxic?

Feb 02 2025

Although the viscosity of screen printing ink and offset printing ink is relatively close, considering the differences in all aspects mentioned above, the two cannot be shared

Feb 01 2025

I hope this article can help relevant companies make wise decisions on the selection of printing ink for paper cups and bowls, and produce high-quality products that are both environmentally friendly and aesthetically pleasing.

Jan 31 2025

Although flexographic water-based ink has significant environmental advantages, it cannot be directly used for offset printing based on current technology and processes. The development of the printing industry cannot be separated from technological innov

Jan 30 2025

Water-based ink uses water as the main solvent, offering environmental friendliness, non-toxicity, and no irritating odor. Its viscosity generally ranges between 200 - 2000mPa·s, relatively low.

Jan 29 2025

The viscosity of flexo ink is medium, with water-based flexo ink typically ranging between 200 - 2000 mPa·s. Solvent-based and UV flexo inks also fall within this range,

Jan 29 2025

In the field of flexographic printing, the choice of ink directly affects multiple key factors such as printing quality, cost, and environmental friendliness. UV ink and water-based ink are currently the two most common choices,

Jan 27 2025

the printing industry is also actively seeking greener and more sustainable production methods. Flexographic water-based ink, as an environmentally friendly ink, is receiving increasing attention in the field of paper cup printing.

Jan 26 2025

To solve the problem of insufficient adhesion of flexographic water-based ink on non-woven fabrics, it is necessary to start from multiple aspects such as ink formula optimization, non-woven fabric surface treatment, and printing process improvement

Jan 24 2025

The application of water-based inks in the printing industry is increasingly widespread, with their environmental protection characteristics aligning with the current concept of sustainable development. Many industries with high safety requirements

Jan 23 2025