RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Gravure printing is renowned for its ability to produce high-quality prints with vibrant colors and fine details. Traditionally, gravure printing has relied heavily on solvent-based inks, but with growing concerns about environmental impact and increasing

Jan 08 2025

ravure ink issues can have a significant impact on print quality, operational efficiency, and costs. By understanding the common problems that arise with gravure ink—such as smudging, poor adhesion, ink misting, uneven coverage,

Jan 07 2025

Water-based varnishes are widely favored for their clear, protective finish and environmentally friendly composition. However, one common concern among users is whether these varnishes are prone to yellowing over time

Jan 06 2025

Selecting the right ink for napkin printing is essential for delivering safe, visually appealing, and eco-friendly products. Water-based ink offer excellent options for most applications,

Jan 03 2025

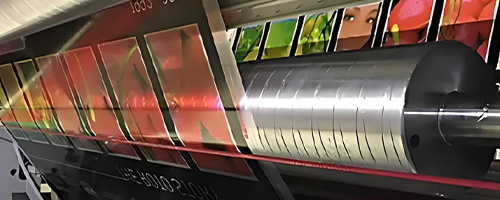

Rotogravure printing is a high-quality, high-speed printing process commonly used for packaging, magazines, and decorative prints. It involves the use of engraved cylinders to transfer ink onto the substrate

Jan 02 2025

ater-based varnish is a popular choice for protecting surfaces due to its eco-friendliness, quick drying time, and clear finish. However, one common question arises: Is water-based varnish waterproof?

Jan 01 2025

When it comes to choosing a varnish for protecting and enhancing surfaces, two primary options dominate the market: water-based varnish and oil-based varnish. Both types have distinct characteristics, advantages, and applications,

Dec 31 2024

The demand for eco-friendly solutions has never been greater. Water-based varnishes have emerged as a leading choice for enhancing the visual appeal and durability of packaging materials while aligning with sustainability goals.

Dec 30 2024

Water-based inks are transforming the way fries boxes and other food packaging are printed, offering an eco-friendly, food-safe, and high-quality alternative to traditional inks. By adopting these inks, businesses can reduce their environmental impact

Dec 28 2024

While RGB is the ideal choice for digital displays, CMYK dominates the printing industry due to its suitability for subtractive color mixing on physical media. Understanding the differences between these models and their respective

Dec 27 2024