RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

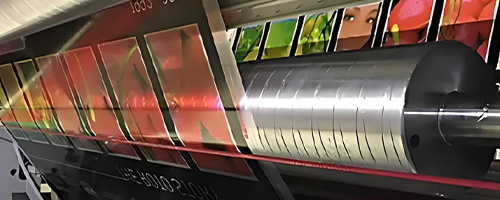

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Asia’s food-grade ink manufacturers are at the forefront of delivering safe, sustainable, and high-performing solutions for the global packaging industry. From innovative formulations to strict compliance with safety standards

Dec 16 2024

Food label printing inks play a pivotal role in the food packaging industry by ensuring safety, compliance, and quality. As consumer expectations and regulatory demands continue to rise, innovation in this niche field is more important than ever

Dec 16 2024

As environmental concerns grow, businesses and consumers are increasingly seeking sustainable alternatives in all industries, including packaging. Biodegradable food grade inks have emerged as a revolutionary solution

Dec 13 2024

As a leading player in China's food-grade ink industry, Huizhou Zhongzhixing Color Technology Co., Ltd. stands out with its eco-friendliness, safety, abrasion and high-temperature resistance, vivid colors, rapid drying

Dec 12 2024

Choosing the best food-grade ink for packaging requires careful consideration of safety, performance, and environmental impact. Water-based, UV-curable, and solvent-based inks each have their strengths

Dec 11 2024

Food packaging plays a vital role in ensuring the safety, freshness, and appeal of food products. Beyond aesthetics, one critical aspect of food packaging is the safety of the printing inks used.

Dec 10 2024

Printing technologies have revolutionized the packaging and printing industry,offering versatile solutions for diverse applications. Among the most widely used printing methods are rotogravure and flexographic printing.

Dec 09 2024

The typical shelf life of UV flexographic ink ranges from 12 to 18 months from the date of manufacture, depending on the formulation and storage conditions. However, this is not a hard-and-fast rule

Dec 08 2024

Choosing the right UV flexographic ink for high-speed printing involves understanding your specific requirements, from substrate compatibility to curing efficiency. By considering factors like ink performance, press configuration,

Dec 07 2024

Two seemingly unrelated types of ink—UV flexographic ink and tattoo ink—serve very different purposes and are designed for distinct applications. Below, we’ll delve into the fundamental differences between these two inks,

Dec 07 2024