RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

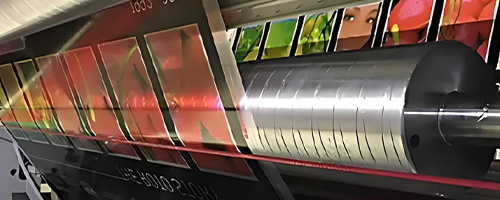

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

In flexographic printing, UV ink is widely used due to its advantages such as fast curing speed, bright colors, environmental friendliness, and energy saving. The viscosity of UV ink is one of the key factors affecting printing quality

Oct 09 2024

In recent years, many screen printing inks have changed from oil-based inks to water-based inks, resulting in many quality issues during the printing process, as there are significant differences between water-based and oil-based inks.

Oct 09 2024

Food grade water-based ink is a printing ink designed specifically for food packaging and other materials in contact with food. It not only has excellent printing effects, but also possesses various unique properties

Oct 08 2024

Food grade water-based ink is a printing material designed for food packaging and materials in contact with food. Many of the food packaging materials we come into contact with in our daily lives are printed using food grade water-based ink

Oct 07 2024

Gravure ink is a type of ink used in gravure printing. Gravure printing is a common printing method that is suitable for printing many different types of materials, such as paper, plastic film, metal foil, etc.

Oct 07 2024

The additive of gravure ink, also known as additive, is an auxiliary component of ink used to adjust the printing suitability of the ink.

Oct 06 2024

The regulations of the US Food and Drug Administration (FDA) for food grade water-based inks are mainly covered in its Federal Food, Drug, and Cosmetic Act and related regulations. The following are FDA regulations on food grade water-based inks.

Oct 03 2024

Water based ink is a uniform paste like substance composed of binders, pigments, additives, and other substances. Its classification methods are diverse, and the following are some of the main classification methods:

Oct 03 2024

In the vast field of printing technology, water-based ink and water transfer ink are two important types of ink, each with unique characteristics and a wide range of application scenarios

Sep 30 2024

UV flexographic ink, as an efficient and environmentally friendly printing material, has been widely used in the modern printing industry. In the printing process of UV flexographic ink, a series of problems may also be encountered

Sep 30 2024