RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

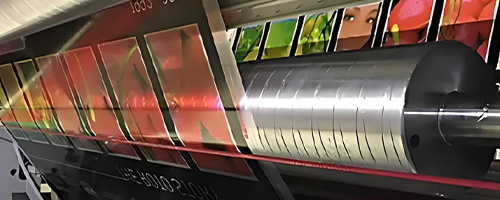

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Huizhou Zhongxing has conducted in-depth research and improvement on the glossiness of water-based ink, which has greatly improved its glossiness. In some non absorbent materials, it is even not much worse than oil-based ink.

Jan 22 2025

Zhongzhixing water-based inks excel in particle size control, utilizing advanced grinding and dispersion technology, along with a strict quality inspection system, to ensure their particle size is less than or equal to 10 micrometers

Jan 21 2025

water-based and solvent-based inks for gravure printing have their unique characteristics in cost composition. In terms of raw material costs, water-based inks have gradually demonstrated advantages; in terms of printing equipment costs, the initial inves

Jan 20 2025

Gravure water-based ink printing on PE films brings environmental advantages to the packaging and printing industry, but it is also accompanied by a series of challenges. Problems such as poor adhesion, color deviation, drying difficulties

Jan 17 2025

heat-resistant UV flexo inks are essential to maintaining print integrity and performance under challenging conditions. These inks are specially formulated to resist the effects of elevated temperatures, ensuring that the printed materials retain their qu

Jan 16 2025

UV flexo inks are an excellent choice for shrinkable film printing, offering numerous benefits in terms of print quality, durability, efficiency, and sustainability. With their ability to deliver vibrant, high-quality prints that withstand the shrinkage p

Jan 15 2025

When it comes to protecting and enhancing the appearance of wood, choosing the right varnish is crucial. Two of the most popular types are water-based and oil-based varnishes, each with its own unique characteristics, advantages

Jan 14 2025

UV flexo inks have become increasingly popular in the packaging industry due to their ability to meet these demands and more. Cured by ultraviolet light, UV flexo inks offer a wide range of benefits that make them ideal for packaging applications across d

Jan 14 2025

UV flexo printing has become a dominant choice for various packaging and label applications due to its high-quality prints, fast curing times, and eco-friendly benefits. UV flexo inks are cured by ultraviolet light, allowing for vibrant,

Jan 10 2025

In simple terms, the solid content of a printing ink refers to the proportion of non-volatile components that remain after the ink dries or evaporates. This includes pigments, resins, and other additives that contribute to the ink’s color, adhesion

Jan 09 2025