RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

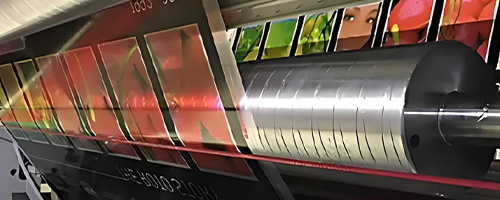

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Food-grade ink is specially designed for printing on food packaging, food labels, and food-contact materials with safety in mind. Its formulation and production process must comply with strict food safety standards to ensure that no chemical

Mar 13 2025

Water-based inks for gravure printing are considered mature, and in the short term, paper packaging and printing processes are the priority areas for replacement; In the long run, it is necessary to collaborate with ink factories in the industrial chain t

Mar 12 2025

UV inks are emerging as an industry favorite with a 7.2% annual growth rate, redefining environmental and efficiency standards through their 100% solids content, zero VOC emissions, and 0.1-second curing speed.

Mar 11 2025

Ethylene Oxide (EO) sterilization is a widely used method for effectively eliminating microorganisms, ensuring the safety of medical devices. Accurately determining whether the sterilization process has achieved its intended results is critical.

Mar 10 2025

Zhongzhixing water-based ink has an outstanding performance in terms of drying properties. While ensuring its environmental protection advantages, it has greatly optimized the drying efficiency

Mar 07 2025

Flexographic printing is widely used in packaging, labeling, flexible packaging, and other fields. Due to its environmental friendliness, high-speed printing, and other characteristics, it is favored by printing factories.

Mar 06 2025

Sterilization indicator labels are common tools for verifying the effectiveness of sterilization. Their core function is to visually reflect whether the sterilization process is completed through color changes.

Mar 05 2025

Zhongzhixing sterilization indicator ink comprehensively covers a variety of sterilization methods. Whether it is steam sterilization, ethylene oxide sterilization, or hydrogen peroxide plasma sterilization, etc., it can be accurately adapted.

Mar 04 2025

Sterilization is the core link in ensuring the safety of medical products. Ethylene Oxide (EO) sterilization, with its high efficiency, is widely used in the disinfection of medical devices, pharmaceutical packaging, and laboratory consumables.

Mar 03 2025

Gravure printing, with its advantages of high precision, high color reproducibility and high production efficiency, is widely used in fields such as packaging, publishing, and decorative materials. Whether it is food packaging, cosmetic boxes

Feb 28 2025