RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

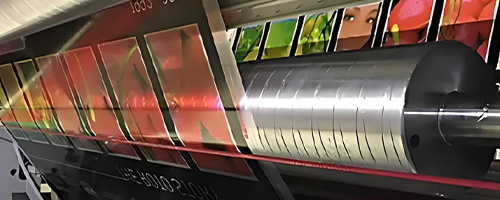

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Compare printing quality differences between water-based and solvent-based flexo inks: color, adhesion, drying & precision. Expert guide for ink selection in packaging scenarios.

Aug 06 2025

Learn proven methods to ensure color consistency with water-based flexo inks. Control ink stability, process parameters, and environment to reduce ΔE to ≤1.5. Includes case studies and actionable solutions for flexographic printing.

Aug 05 2025

Discover how water-based flexo inks adapt to high-line anilox rollers (600+ LPI) with nano-grinding & low-viscosity formulas. Solve clogging issues, boost precision, and cut costs. Expert guide & case studies included

Aug 04 2025

StarColor Fast Drying Flexographic Ink boosts flexible packaging productivity with 40% faster drying, compatible with BOPP, PET aluminized films. FDA-compliant. Request samples to reduce costs now!

Jul 31 2025

Discover how a Guangdong printing enterprise upgraded high-end paper bag printing through cooperation with Zhongzhixing's flexographic water-based ink, achieving improvements in efficiency, quality and access to international markets.

Jul 29 2025

Learn how to select the right flexographic ink—water-based, solvent-based, or UV—based on ink properties, press types, and printing substrates. A complete guide to flexo printing technology

Jul 28 2025

Compare the real costs of water-based flexographic ink and UV ink, including ink price, energy use, equipment, and maintenance. Find out which saves more.

Jul 25 2025

Starcolor offers customized flexographic ink formulas for food packaging, ensuring global compliance, high durability, and perfect fit for substrates and machines.

Jul 24 2025

Discover how water-based flexo inks elevate the brand value of pet food packaging by aligning with sustainability goals, offering low VOC emissions, food-safe formulations, and vibrant shelf appeal.

Jul 22 2025

With the tightening of environmental regulations, water-based flexographic ink is gradually entering the field of flexible packaging printing. This article explores the performance challenges and technological breakthroughs in printing adaptability, adhes

Jul 21 2025