RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

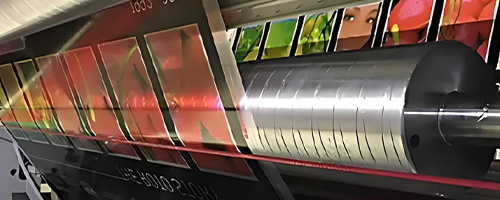

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Monomer choice and polymerization efficiency are key factors influencing migration in UV inks. Learn how selecting the right monomers and optimizing curing helps achieve low migration and regulatory compliance.

Jul 18 2025

How do UV and water-based inks compare in terms of migration risk? Learn about the mechanisms, influencing factors, and regulatory implications of ink migration for food and pharmaceutical packaging.

Jul 17 2025

Photoinitiators play a crucial role in UV ink curing—but in low migration systems, the wrong choice can compromise food safety. Learn how selecting the right photoinitiators ensures regulatory compliance and low migration performance.

Jul 16 2025

Explore the key global regulatory standards that define "low migration" inks for food and pharmaceutical packaging. Understand EU 1935/2004, Swiss Ordinance, FDA compliance, and their impact on ink formulation.

Jul 15 2025

Learn how crosslinkable resins enhance chemical resistance in water-based inks. Discover Starcolor’s advanced resin systems for durable, eco-friendly printing on demanding substrates.

Jul 14 2025

Explore how hybrid resin systems improve water-based ink adhesion on PE and PP films. Learn about advanced formulations for flexible packaging and non-polar substrates.

Jul 11 2025

Compare UV flexo inks and traditional inks for scratch resistance. Discover why UV-curable inks offer superior durability, hardness, and protection in label and packaging printing.

Jul 10 2025

Learn how to prevent yellowing in UV flexo varnish for label printing. Discover Starcolor’s non-yellowing formulations and best practices for long-term clarity and stability.

Jul 08 2025

Discover Starcolor’s UV flexo inks engineered for no-cracking performance on flexible packaging. Superior flexibility, adhesion, and fast UV curing for high-speed converting.

Jul 07 2025

Learn about the shelf life and storage requirements of thermochromic inks. Discover how to store color-changing inks safely and extend their usability with tips from Starcolor.

Jul 05 2025