RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

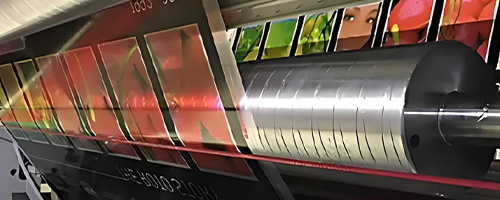

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Recently, someone asked about the issue of color fading when printing plastic woven bags with water-based ink. Therefore, I have compiled a list for your reference:

Jul 24 2024

UV flexographic ink, also known as UV curable ink, is a type of ink that is rapidly polymerized and solidified by adding a certain amount of monomers and additives to the ink under UV irradiation

Jul 24 2024

Water based ink is a printing ink system that uses water as the main solvent or dispersion medium. It abandons the extensive use of organic solvents in traditional solvent based inks and instead uses water-soluble resins as connecting agents,

Jul 24 2024

When printing paper bags with UV flexographic ink, a series of problems may be encountered. To address these issues,

Jul 23 2024

With the increasing awareness of environmental protection, water-based ink, as a new type of environmentally friendly printing material, has been widely used in the printing of daily necessities such as napkins

Jul 23 2024

Water based ink, as an environmentally friendly and non-toxic printing material, is increasingly widely used in the field of napkin printing. Napkins have particularly high safety requirements due to their need to come into contact with the human body

Jul 23 2024

Water based ink, as an environmentally friendly printing material, has been widely used in the field of plastic packaging, especially in the printing of BOPP (biaxially oriented polypropylene) films. However,

Jul 22 2024

In the current era of pursuing sustainable development, water-based ink, as an environmentally friendly and efficient printing material, is gradually emerging in the field of plastic woven bag printing and showing broad application prospects.

Jul 22 2024

In the packaging industry, BOPP (biaxially oriented polypropylene) film is highly favored due to its excellent physical properties and wide range of applications. However, in today's pursuit of both environmental protection and efficiency

Jul 22 2024

In the UV ink printing process, color consistency and accuracy are crucial for product quality. However, in practical operation, color difference problems are often encountered, which not only affect the aesthetics of the product,

Jul 19 2024