RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

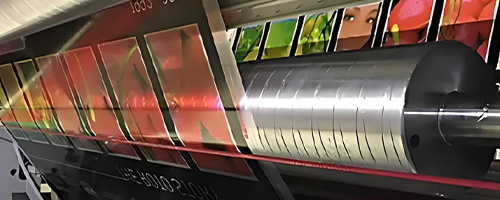

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

UV ink, the full name of ultraviolet curing ink, is a special ink that can quickly cure into a film under ultraviolet (UV) irradiation. It is unique in that its drying process does not rely on traditional solvent volatilization

Aug 04 2024

UV ink achieves rapid drying effect through UV irradiation. Currently, the main UV light sources are mercury lamps and LEDs. Next, we will compare the characteristics of the two light sources

Aug 02 2024

In daily life, napkins as a frequent guest on our dining table, are receiving increasing attention from consumers for their safety and environmental friendliness.

Aug 01 2024

Printed patterns on napkins are not only for their appearance, but also for advertising purposes. A beautiful pattern on napkins can leave a deep impression on customers

Aug 01 2024

At the same time, paper bags also have good weight capacity. Paper bags are simpler to print than plastic bags.

Aug 01 2024

When water-based ink is used to print PET film, if there is insufficient adhesion, it may be caused by various factors. The following is a detailed analysis of possible causes

Jul 31 2024

Many people ask if water-based ink can be used to print adhesive labels. Of course, it is possible. Water based ink can already be printed on paper and plastic film surfaces. Let's take a look at some of the advantages

Jul 31 2024

When printing napkins with flexographic water-based ink, a series of problems may be encountered, mainly involving ink performance, paper characteristics, printing equipment, and operating environment.

Jul 31 2024

Which is more environmentally friendly, flexographic ink or offset ink? I believe many people already know that flexographic ink is mostly water-based ink

Jul 30 2024

Flexographic ink is an ink specifically designed for flexographic printing technology. It is mainly based on water-based or alcohol based systems, mixed with pigments, water-based or alcohol based resins,

Jul 30 2024